20230218_085456e.jpg

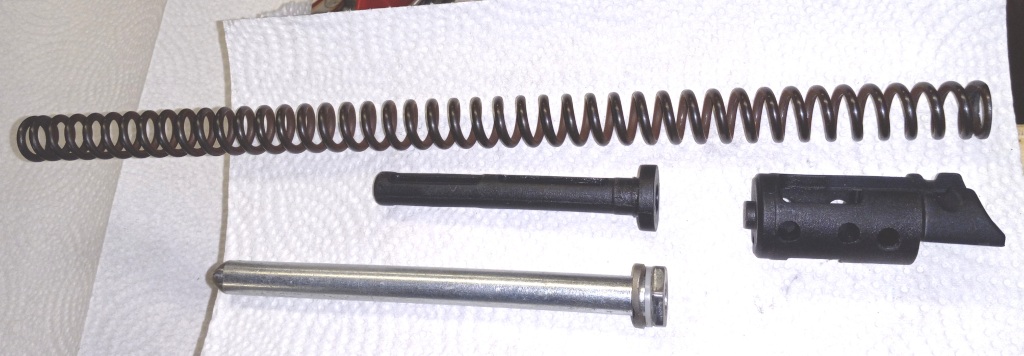

First image is my Mod95 Vortex air spring, obviously it has lost all its air AGAIN (3rd time?), and the actual Mod95 piston.

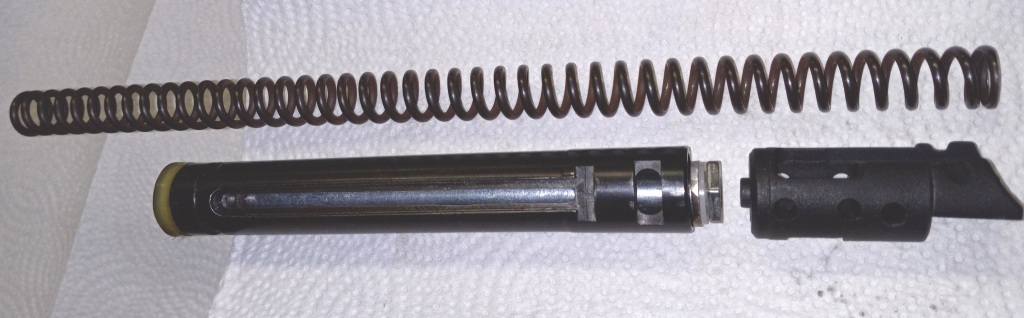

Looking at the Vortex Type 1 you can see the bleed screw, cross-pin hole, and near the top the fill port hole.

Note the CRACK running down the middle of the milled cocking slot in the piston ?! That was not there last time I worked on this rifle.

20230218_085529e.jpg

Next image is same piston but other side of Vortex. That is a better view of the larger fill port hole and the smaller cross-pin hole. The text on this Vortex says “Maximum Muzzle Velocity at 125 Bar” and “Do not fill more than 160 Bar. I experimented with 150 Bar awhile back and it was WAY TOO MUCH PRESSURE for this rifle. Back to 125 Bar and it was a JOY to shoot. Mid to high 700fps for 14.3 grain CPHP and better accuracy than the shooter (me;-)

I was getting ready to TIG weld the crack in the piston and resurface/polish the cocking slot. That is when I noticed how THIN the metal was at the center of this slot. Seemed to be 0.005″ which may be why it split. My TIG welding is fair but if I had attempted to weld this crack it would have been an ugly mess!

I chose to grind out a channel instead, back to unfractured metal, and deburr the edges. Smoothed up the result and tested how the cocking shoe “rode” the modified piston slot. Nicely smooth! I’m deciding this is good enough.

MANY other springer pistons have the slot milled all the way through so you can see the spring coils inside so I don’t believe this has significantly weakened the piston. Only a tiny amount of mass was removed so the modified piston should not affect the rifle performance in any measurable way.

20230218_103227e.jpg

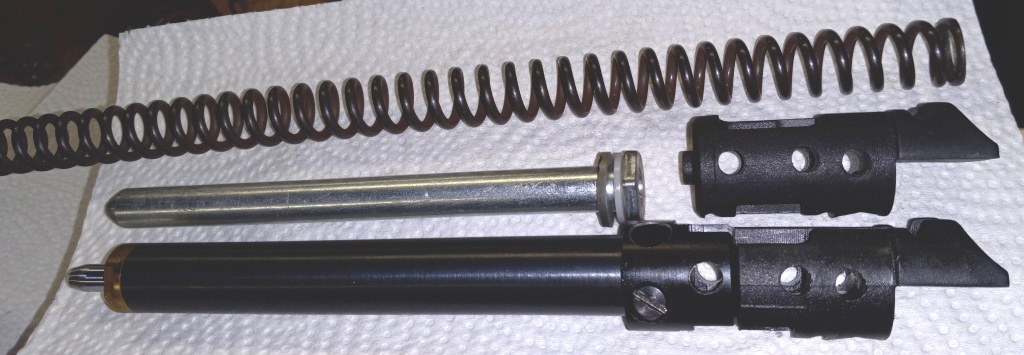

Next image shows the stock factory Mod95 spring I ordered. Also one of the 3 hole endcaps designed for coil spring models. The stock spring guide, which I don’t plan to use, is from another Mod95. It is too short and too loose a fit to work as a proper spring guide. Last is my custom spring guide made from a steel bolt. I added a slippery polymer washer and a hard steel washer, along with a little moly paste, to make a “thrust bearing” so the spring can wind-up (rotate) and relax during the cocking/shot cycle with minimal friction.

20230218_103646e.jpg

Image of the parts with the modified slot piston. So far an ideal fit as planned.

20230218_103434e.jpg

Here I’ve added the dead Vortex with its specific endcap as a comparison to the coil spring and its specific endcap. The “coil spring” endcap is NEEDED for this conversion. IMO the coil spring endcap is also needed for NP conversions. An NP conversion will need an additional custom bushing for centering and proper preload, but that is a fairly simple part which can be fabricated with basic home power tools.

https://www.gatewaytoairguns.org/GTA/index.php?topic=196304.msg156286955#msg156286955

Will reassemble the Mod95 using parts shown, along with my favorite lubrication process, and begin testing velocity and accuracy grouping after a 20-50 shot break-in period. May simply add that data to this post or start a new post as a part “b”.

mjb 🙂

UPDATES 02/18/2023:

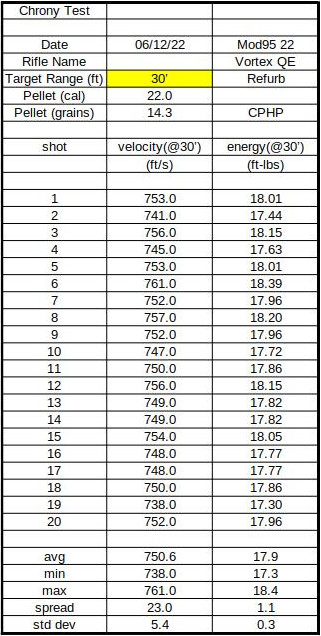

First chronograph table data taken June 12, 2022 after Vortex leaked to “0” and was then restored to 125Bar.

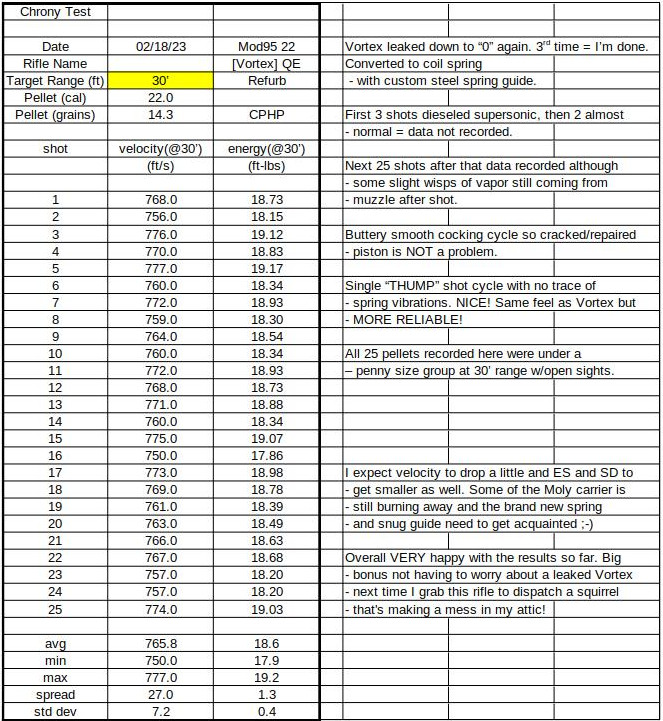

Second data table is from today 02/18/2023 after converting Mod95 to a coil spring with custom spring guide.

All is working well so far.

mjb 🙂