Winchester/Daisy 1100ss Break-Barrel Air Rifle ( first draft, no images)

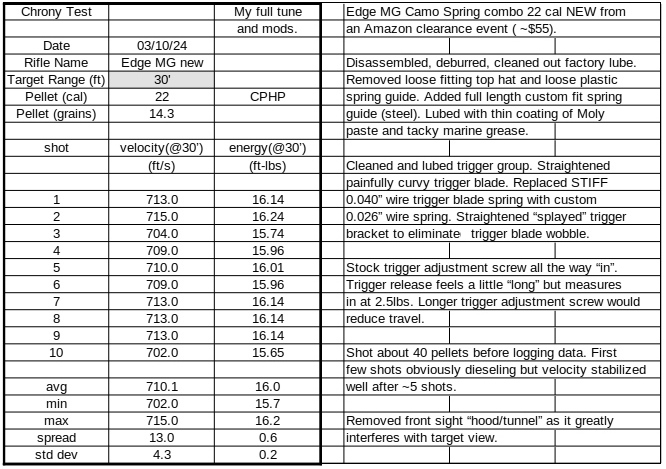

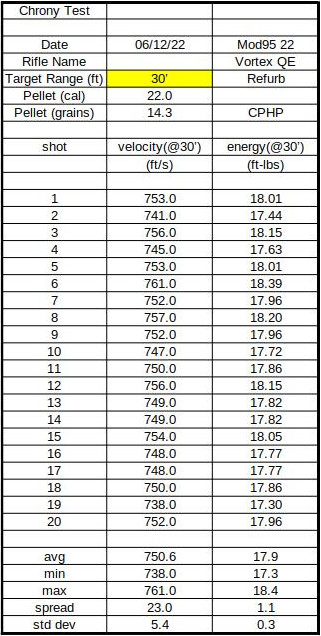

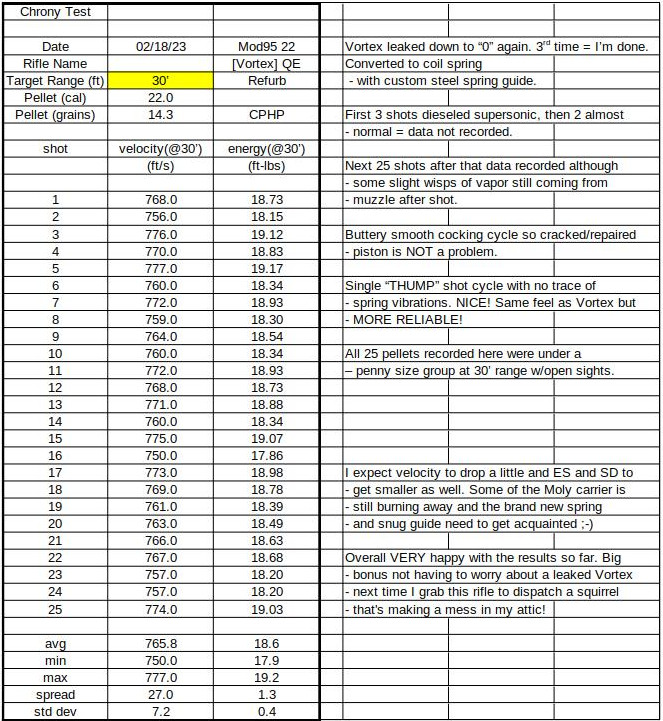

Not quite what I would call a magnum springer, but certainly an adult sized air rifle shooting in the 16 fpe range right out of the box. I define magnum springers as starting around 22 fpe and up. What I’ll be discussing today is one of my $29 1100ss versions from ~2019 Amazon clearance that had factory stock internals and some trigger mods shown here…

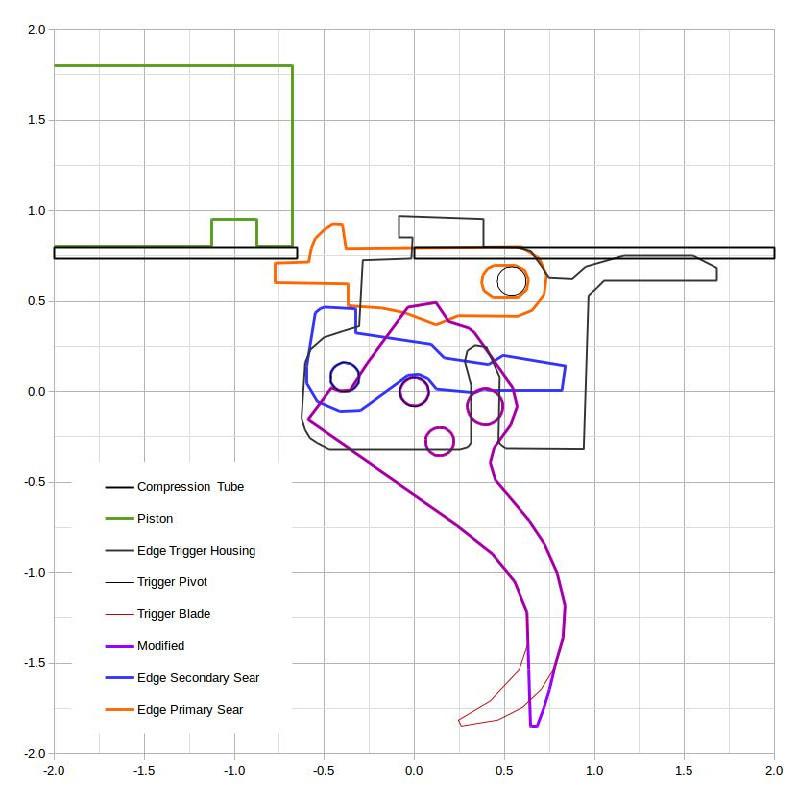

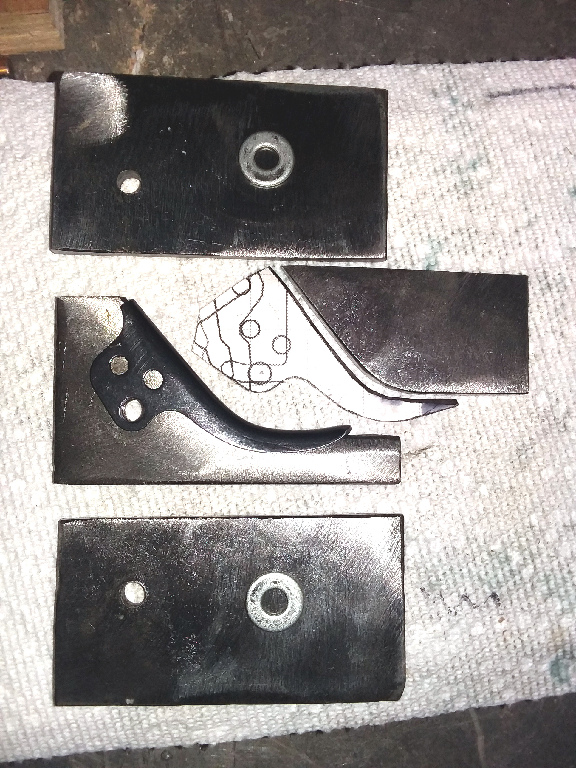

Winchester/Daisy 1100ss Trigger Mods

IMO the rifle shoots well and (with the trigger mods) I can get shockingly consistent 3/8″ 10-shot groups at 30′ with the open sights. For me and my dozens of other springers this accuracy/consistency ranks in the top 5. Considering the $29 cost of the rifle I was impressed. I am still impressed after a recent shooting session with the same results. My very first 1100ss was a $63 one from a local Walmart and that rifle (with trigger mods) is also shooting the same way. IMO a bargain at $63 and a steal at $25.

I don’t feel the cocking cycle or the shot cycle is anything other than “normal” for this category of springer. Typical action noise dominates the shot cycle. I’d rate the polymer stock as BETTER than average without any hollow resonances I frequently find in cheap springers.

Muzzle report is also typical. Obviously anything supersonic (from dieseling factory lube) will be LOUD, but this should subside after a few shots. Any slight crunchiness near the end of the cocking stroke is usually due to the anti-bear-trap and safety reset linkage. I feel this on several budget springers and don’t consider it a problem.

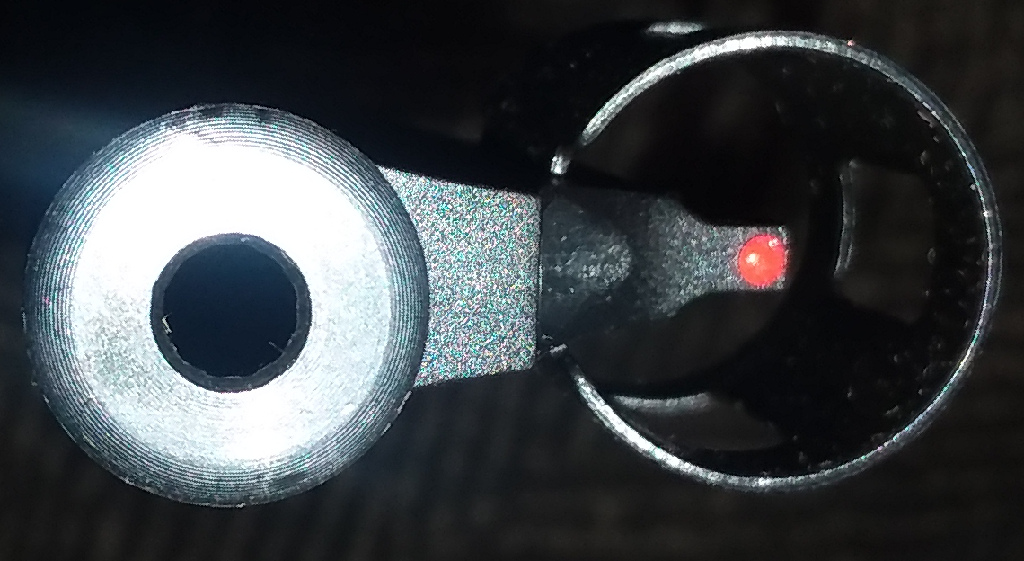

There was one comment about sharp edges on the front sight making the cocking cycle uncomfortable. I AGREE! Something to investigate at a later date.

There has been some discussion of ways to modify this rifle so it is easier to shoot. Removing the top-hat mass and cutting a few coils off the main spring are practical options to drop the muzzle fpe and reduce the shot-cycle movement.

I have tried similar on other harsh shooting “budget” springers with some success. Better fitting guides, removing some preload and moving mass (removing a top hat) and adding a little more tacky spring grease can all smooth out a harsh shot cycle at the expense of a few fpe. IMO this is an excellent trade-off when it makes the rifle more fun and accurate to shoot.

However, trying to make a large solid (heavy) 16fpe springer shoot well at 8fpe is IMO not the right approach. I’ve tried it, it can be done, but I’ve restored all my sub 10fpe “experiments” BACK to near factory ratings because they had some quirky shot cycle anomalies. A really annoying one was a pronounced piston bounce that seemed to occur as the pellet was exiting the muzzle. THUMP….thump! Like a weird heart beat!

Obviously anyone can do whatever they want to their cheap ($25-$60) entry level springers. However, my recommendation is to tweak a rifle NEAR its design ratings to find a sweet spot for comfortable shooting and best accuracy. If the goal is to have an 8fpe springer, then START with one that is rated NEAR that from the factory!

I had the urge to shoot a sub 10fpe springer so I finally went out and bought one (or two). My first was a Hatsan Alpha youth rifle shooting around 5fpe. IMO this is EXACTLY what I was looking for. A small scale springer that was a pure joy to shoot. Super light cocking effort and no significant spring recoil. EASY to stack 500fps pellets at my 30′ range with open sights. If glass is preferred there will be no scope damaged or wandering POA problems with this MILD springer.

There are other youth options in this size/fpe range, but I have no experience with them.

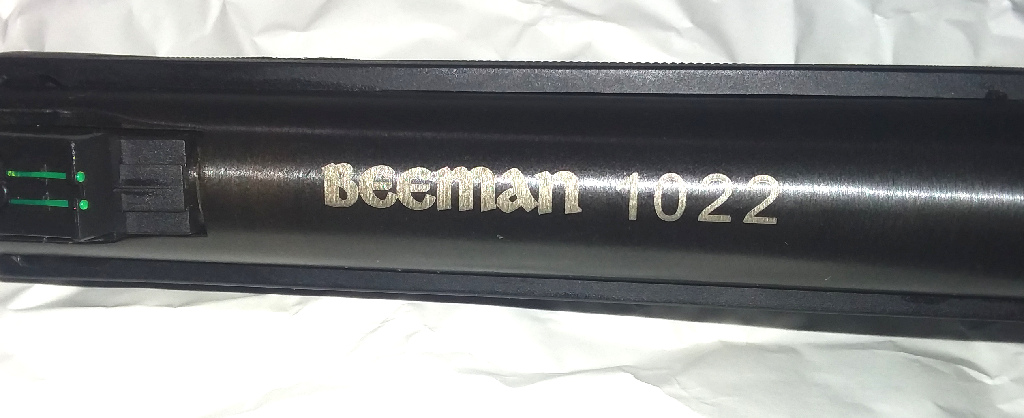

I did acquire a Beeman Black Cub 177/22 from a WM clearance for $45. This rifle shoots the 177 well at around 10fpe so it fits my basement/backyard plinker needs. Biggest problem though is the single stage direct sear HEAVY trigger. Sometimes these triggers can be improved (a little) but it’s also easy to RUIN the trigger and make the rifle unsafe/unusable if you go a little too far.

Beeman Black Cub Review Link

Working on the 1100ss INTERNALS:

>Remove the stock, (3) M6 screws.

>Remove the anti-bear-trap & safety-reset bar by unhooking the spring and sliding the bar towards the muzzle.

>Remove the safety leaver, one short pin with E-clip and one skinny longer pin, it should fall right out.

>Remove the trigger blade AND its bracket, one short pin with E-clip.

>Remove the rear socket head cap screw (5mm hex).

>Remove the rear plastic cap by gently tapping out the larger cross-pin (REAR PIN).

On my rifle the smaller cross-pin (FRONT PIN) was holding all the spring pressure.

>IF you have the trigger mod set-screw installed, back it out ~3 turns NOW so the trigger group can slide out without interference.

>Remove the trigger assembly by gently tapping towards the rear, it should move and pop out with minimal effort.

Getting the trigger group back in with the main piston latch in the correct position is a REAL CHALLENGE!

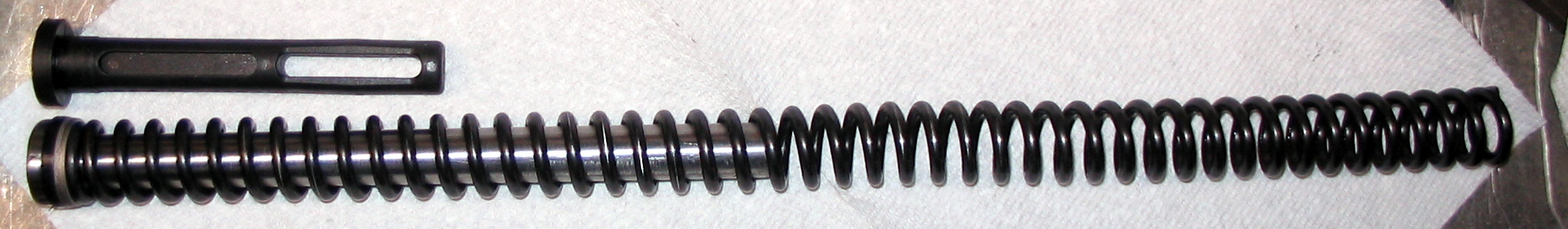

>IN A SPRING COMPRESSOR put some force on the center steel spring guide until the smaller FRONT cross pin can be gently tapped out.

>Slowly relieve spring compression until rear spring guide assembly can be safely removed.

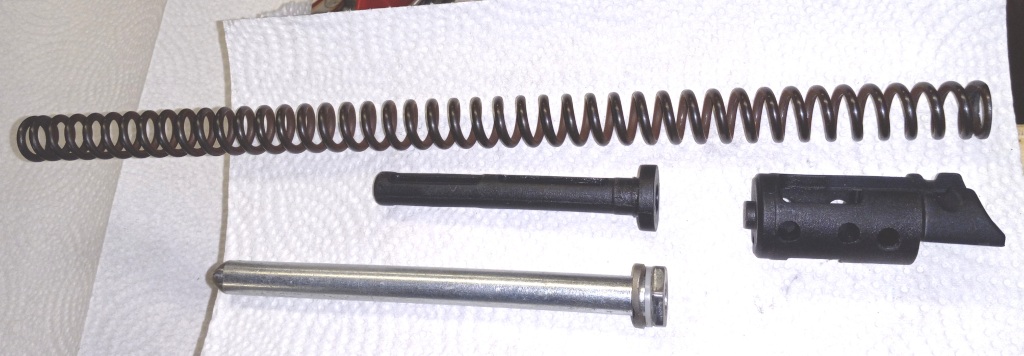

>Remove spring and top hat.

>UNLATCH barrel and remove the pivot bolt locking screw and pivot bolt.

Barrel assembly should slide out from between the forks and the cocking link/shoe can be freed from the cocking slot.

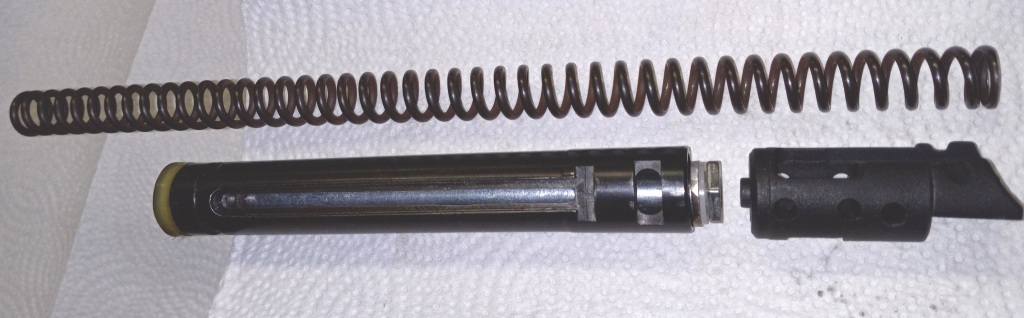

>Piston can now be removed from the compression tube.

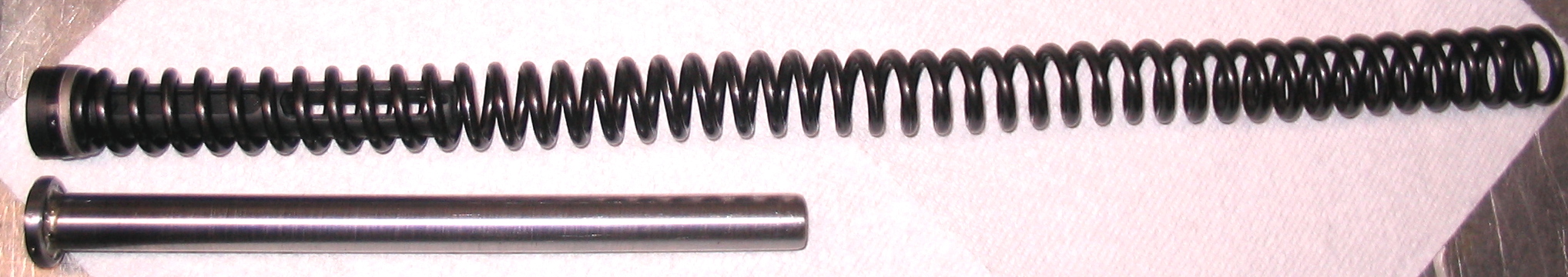

Spring & piston had a heavy coating of VERY tacky grease. Rifle was NOT obviously dieseling, but I think THAT GREASE is why this rifle shoots fairly well right out of the box. The super loose fitting top-hat and a laughably short and loose fitting spring guide don’t do anything to support the spring or dampen spring vibrations. In this case the sticky factory grease is working well IMO.

My rifle had what looked like either rust or very hard dry crusty brown factory grease in the REAR HALF of compression tube. This is the section from where the cocking slot STARTS going rearward. The FRONT part of the compression tube, where all the compression magic occurs, was highly polished. That shiny part is EXACTLY what it needs to be and I ONLY wipe out the excess factory lube from that section. NO scrubbing or cross-hatch honing! That is for steel ringed pistons in IC engines! NOT for springer compression tubes! I WANT a shiny & polished surface for the slippery polymer piston seal or o-ringed piston options.

The rear crusty section had lots of cutout burrs and some galling (NOT from piston skirt, just factory finish slack) where the cross pins reside. I used a small needle file to de-burr all the cutouts. Then I chucked up some Scotchbrite on a dowel and using a hand drill polished the REAR half of the compression tube until it was almost as smooth as the front section. No need to go crazy here, I just wanted a SMOOTHER pathway for the piston seal so it wouldn’t get SLICED UP during reassembly.

Some interesting dimensional NOTES:

Spring Dimensions

Free Length, 11″, 279mm

Active Coils, 35

OD, 0.762″, 19.4mm

Wire Diameter, 0.128″, 3.3mm

ID, 0.505″, 12.8mm

(I have not found a direct cross reference to a “drop in” Vortek spring)

Piston Seal Dimensions

Thickness, 0.245″, 6.2mm

Min ID, 0.485″, 12.3mm

Max ID, 0.645″, 16.4mm

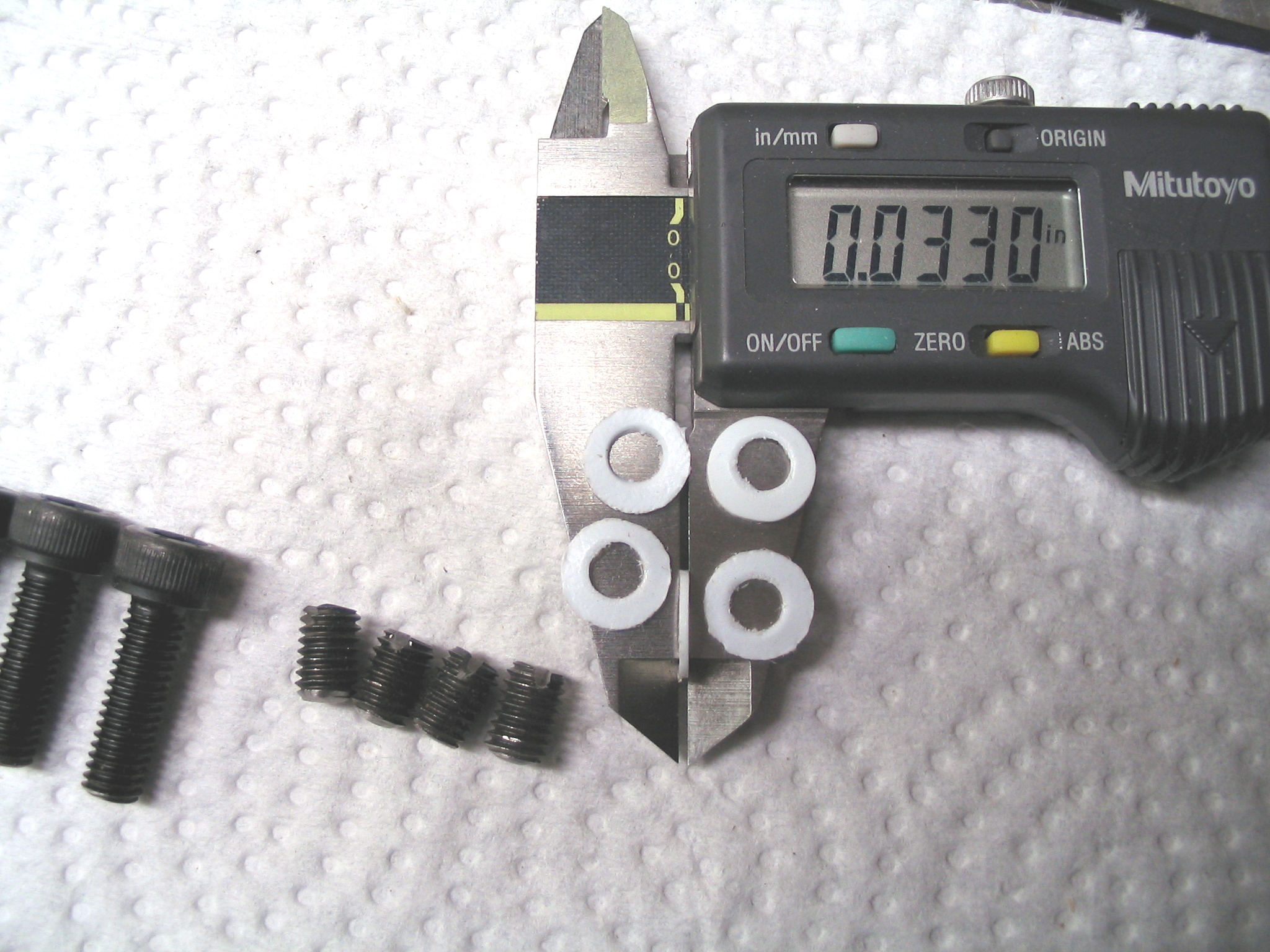

ID Flat, 0.039″, 1.0mm <this is interesting!?

ID Taper, 0.206″, 5.2mm

Max OD, 1.075″, 27.3mm

(I have not found a direct cross reference to a “drop in” Vortek seal)

Dianna 28mm seal I have has similar ID taper but OD is too wide and it is not “thick” enough unless an additional 0.039″ (1mm) thick washer is placed on piston head first.

A Hatsan Small seal has the right OD and thickness but it will NOT fit this tapered button piston head! Hatsan piston seals fit a two-step (straight, not tapered) piston button.

Piston & Seal Weight, 10.7oz, 303g

Top Hat Weight, 2oz, 57g

Moving mass (no spring), 12.7oz, 360g

This is initially bad news for getting easy/cheap replacement wear parts (springs & piston seals) for these bargain rifles. I’ll continue to look for replacement parts and post updates if I find any.

After a thorough de-burr and cleaning I applied my preferred (THIN) moly paste coating to the piston head and skirt and a super light burnished coating to the entire inside of the compression tube.

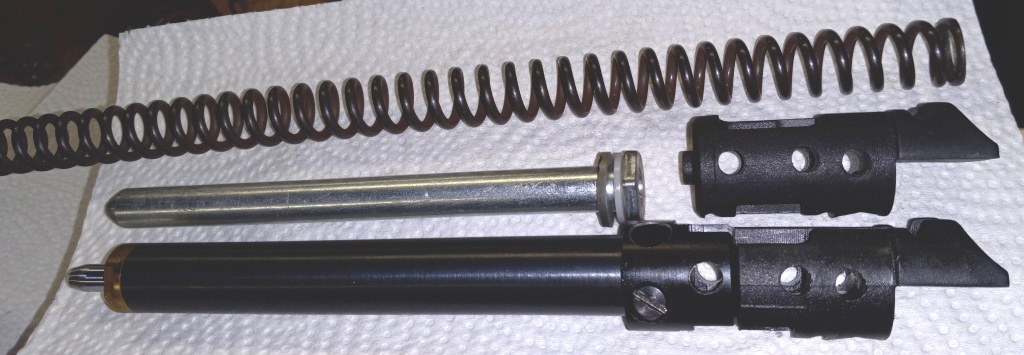

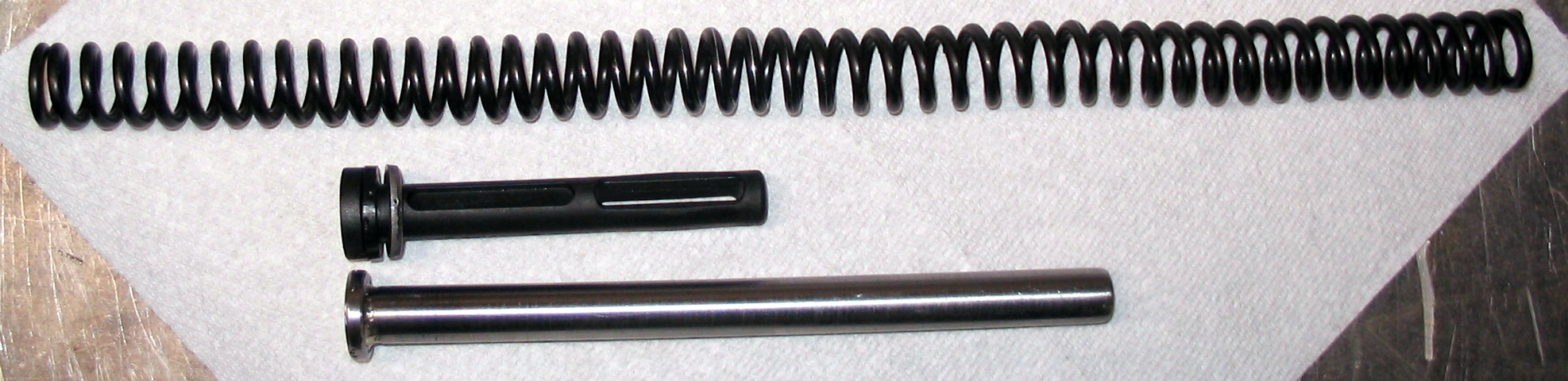

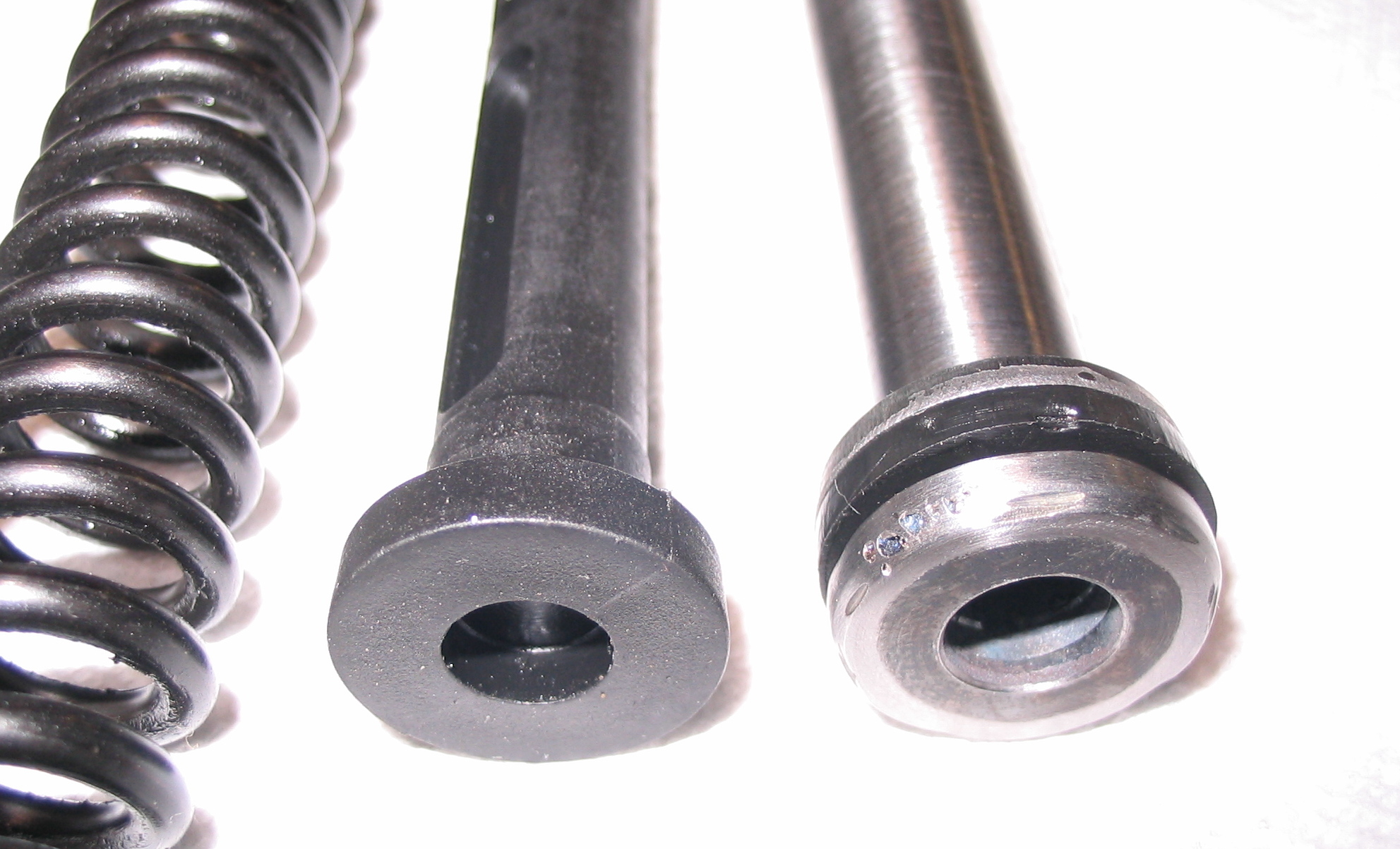

Then I decided to go the against the flow and INCREASE the internal moving mass! I made a new top hat from a 1/2″ hex bolt. Rounded off and polished the hex head and cut it to a length about twice as long as the factory top hat. Double the mass, has an additional 1/8″ preload, AND it fits the spring MUCH BETTER than the really loose factory top-hat. I expected there would be very little difference in the shot cycle. Was hoping the better fit might dampen what little spring vibrations the rifle had and the rifle might shoot heavier pellets slightly better(?). Typically more moving mass is better for heavier pellets.

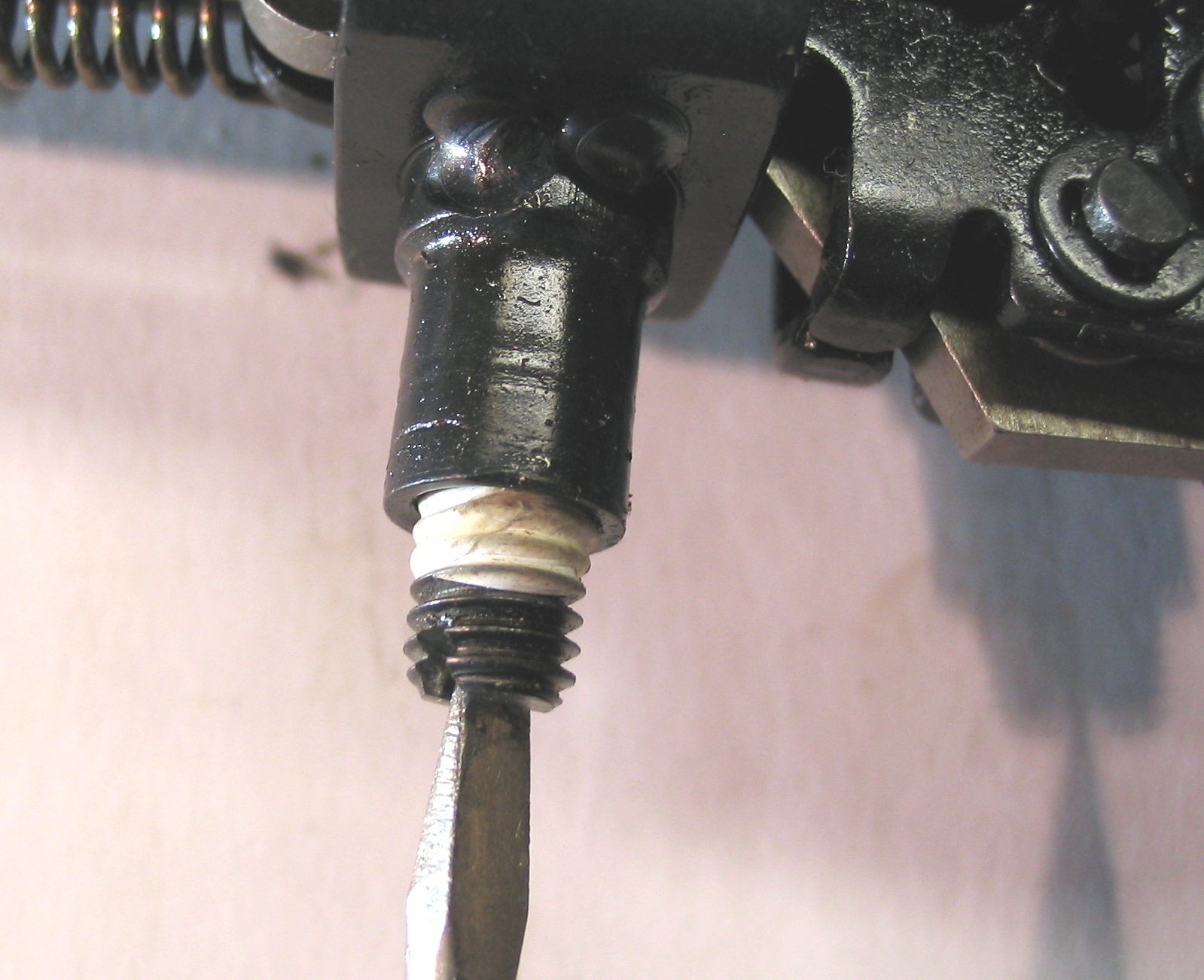

New Top Hat Modification:

Piston & Seal Weight, 10.7oz, 303g

NEW top Hat, 4oz, 113g

Moving mass (no spring), 14.7oz, 417g

I re-assembled the rifle painting the spring and guides with my preferred coating of sticky marine grease.

Getting the small cross pin back in was difficult in my rifle. Aligning 3 things to get the pin seated took some extra time and effort. You DON’T want to POUND these parts back together! If it won’t go back together with gentle tapping from a small plastic hammer, then reposition and try again!

Getting the trigger assembly back in with the main piston latch in the correct position is difficult. You really need 3 hands, but I got it done.

After the small cross pin is installed (spring compressor is required) the rear plastic safety leaver cap slides right in and the large cross pin (at least on my rifle) slides right in 95% with no need for the spring compressor. Large pin only needed a very light tap to get it 100% seated.

Replaced the safety lever, anti-bear-trap linkage, and trigger blade assembly with relative ease. Re-adjusted the trigger set screw mod back to where I like it, about 0.030″ sear overlap.

Mounted action to stock (describe extra washer mod later) and tried to cock the rifle BEING AWARE that my top-hat might have been too long (unlikely) AND my trigger mod was re-adjusted by SIGHT so trigger might NOT be stable.

Rifle cocked just fine and a few hard bump tests indicated I didn’t have the trigger in an unsafe mode.

Next up, shooting for velocity and accuracy along with any subjective observations about the shot cycle and how it may have changed or not.